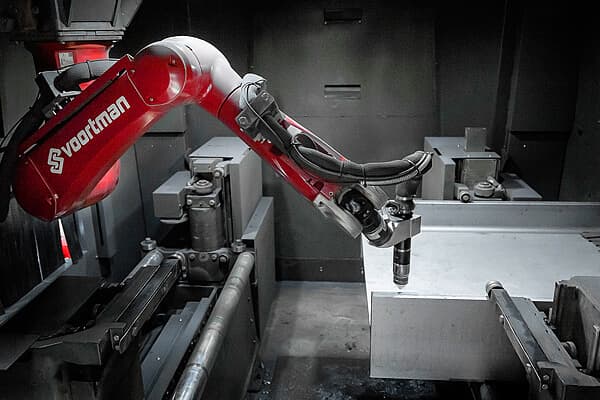

Robotic Coping Machine Massage

The V808 roller-feed measurement and clamping system locks profiles and keeps them in the same exact place throughout processing. The fully automated measuring roller feed system saves time and money by not requiring a pusher or gripper before returning home to load the next piece. Voortman�s roller feed system is fully automated within a standard range for profile processing. Voortman�s automated in-feed crossing transports provide enough stability and support so that beams of up to 15.000kg (33,000 lbs) can be properly positioned and processed.

All it takes is one button to start your production. After importing industry-standard DSTV or DSTV+ files into our VACAM Software's processing list, your operator is free to focus on loading the system and unloading it. To keep up with production speeds, no manual intervention is required.